Hi Mark/Guys

Not sure if you saw my direct message Mark, but I thought I would post here too..

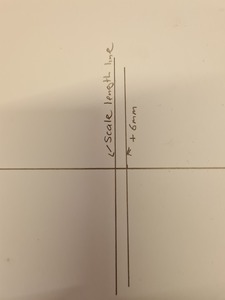

I'm watching the video on aligning the bridge but I'm afraid I got a bit confused...I've attached a few images to explain.

The basic question is whether I am aligning the bridge to the scale length line or the 6mm line drawn behind it. You also mention that the bridge should be offset from the scale length line by 1.5mm and 4.5mm, and this is where I'm confused by the 6mm line. Unfortunately the video doesn't show clearly where you finally lin

e up the bridge.

I'm sure it's me getting confused but any help much appreciated...

cheers

Steve

and this is where I'm confused by the 6mm line.

@steveadams Hey Steve, watch this video. Hope it helps, this is what I did. The bridge does not need to go on an angle for the intonation, that is built into the bridge. Just put it on at a 90 degree angle to the centre line.

Check with Mark and others, check twice and cut one! Good luck!

Make guitars, not war 🌍✌️🎸

Trevor Wilkinson is a smart man. With that type of wrap around bridge, mark out 6mm from the scale lenght which you already did. That line is the mark of your bridge posts where you will drill based on the centers of the posts and it is NOT the starting point of your bridge. From the center line at your 6mm line. Punch 41mm out on both ends. Those are your punch marks for the center of each bridge posts. That is your drill mark. It is 82mm apart from centers of each posts. Hence, 41mm to both sides. Before drilling test on a scrap piece for correct drill bit size for posts to fit accordingly. Generally it is either 11 or 12mm. Now, depth of drill. Posts are generally 20mm deep but give yourself 1-2mm allowance and drill down 21-22mm. Check 4-5 times make sure you are spot on before drilling to the body. I would even go as far as doing a practice run on a scrap piece to make sure your 82mm drill posts fits the bridge just right.

It is 82mm apart from centers of each posts. Hence, 41mm to both sides.

Yeah well said @clinton

Remember @steveadams that everything is measured from the centre line. So when you have measured your 6mm back from the scale length line, measure 41mm out, either side of that mark to get the mark for your two post holes. Clinton has given a good description of what to do and I would definitely take his advice on test drilling in some scrap. Once you have test drilled the holes, put in your bridge posts and check to see if the bridge slides on to them, it should slide on nicely. If you have any issues or further questions, come back here. Good luck.

Make guitars, not war 🌍✌️🎸

Hi Steve

You also mention that the bridge should be offset from the scale length line by 1.5mm and 4.5mm,

Just as Boo and Clinton said, your line at 6mm from the scale line is where you drill your post holes for that bridge. On Mark's video, the 1.5mm/4.5mm line that he's drawn is the intonation line. The Wilkinson bridge cleverly aligns that for you with the posts centred on the 6mm line. Mark also did a livestream that covered this in a bit more detail for various bridges.

wow....perfect...thank you so much....totally answered my questions as I was also a bit confused between the hard edge of the bridge and the actual fixed saddle positions...

I've fitted a few tele bridges and obvs there is more leeway, this is the first time I've come across a fixed bridge like this...

thanks again

Steve

@steveadams No problem, that’s what we are all here for. Like @robin has just said, you don’t need to worry about those intonation measurements with this bridge as they are already built into the bridge itself. Just mark your scale length line onto the guitar body (on some masking tape), measure 6mm back and use your draughting square to strike a line 90 degrees to the centre line. You will then measure out 41mm either side of the centre line on that 6mm line and make a mark for each. They are you post holes to be drilled. Use your calliper to check the diameter of the posts and that is the size of drill bit needed. Check, check, check! Good luck.

Make guitars, not war 🌍✌️🎸

@steveadams I had a bit of a learning opportunity when I fitted my bridge. I had drilled my test hole on a bit of scrap using my pillar drill, the post fitted perfectly. When went to drill the body, the throat depth of pillar drill was short by about 10mm, so couldn't use it. So I used my hand held drill with the same drill bit, I must have been a bit wobbly because the first hole was oversize and the post was a loose fit.

I had the smae thing when I made my first telecaster..the string through holes are a total nightmare and the throat on my pillar drill was too short as well...

I sweated over that one!! but finally worked out a method...

cheers

Steve

When went to drill the body, the throat depth of pillar drill was short by about 10mm, so couldn't use it.

@robin I have also had the same problem and I really wanted to have the experience of installing string ferrules. I did use a hand drill on a couple of builds but I ended up installing a string ferrule block instead of individual pieces, much neater (unlike my hand drilling).

I then decided to build a guitar that allowed me to use my pillar drill to drill the ferrule holes because, as you know, the pillar is normally on the way. This style of guitar allowed me to finally do it, it is an extreme solution though. 🤣

Make guitars, not war 🌍✌️🎸

Thats a neat solution to the pillar drill problem. How comfortable is it to play?

@robin It’s just as comfortable as most other guitars really. It does give you an extra option of playing it in a different position too, a bit like some players do with flying Vs.

Make guitars, not war 🌍✌️🎸

On Mark's video, the 1.5mm/4.5mm line that he's drawn is the intonation line. The Wilkinson bridge cleverly aligns that for you with the posts centred on the 6mm line.

This is the bit I was missing, cheers @robin

My question was whether you needed to align the tailpiece to the bridge ie the intonation line, or if it should be mounted perpendicular to the center line. Also I kept calling the tail piece the saddle because I'm an idiot.

As I understand it now the scale length is measured between the two points that the string is suspended, nut and bridge.

Great stream today guys \m/

As I understand it now the scale length is measured between the two points that the string is suspended, nut and bridge.

Not exactly, the saddles on the bridge will be approximately inline with the intonation line, measuring this won't be the scale length. To find the scale length of an existing guitar (or fretboard), measure from the nut the the centre of the 12th fret wire and double it. And don't put yourself down, were all idiots.