Did you do it by hand or use a small bit?

@mattbeels Thanks man. I did the round over by hand, I always do when it’s so slight. The transition I also did by hand and took inspiration from Satch’s Ibanezes, you know, the ones that look like sucked lollipops. 🤣 Smooth.

Make guitars, not war 🌍✌️🎸

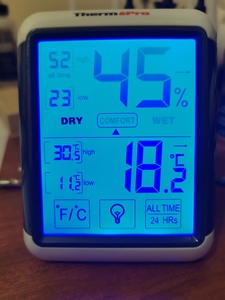

25.5degC ??? How can you work in such heat???

@tv101 Thanks. That metre was actually in the sunlight so that had an effect on the temperature showing. It was probably a few degrees less in the shade.

Look at it now the sun has gone.

Make guitars, not war 🌍✌️🎸

I found time to get back to building this Bansman today. I got the neck back in the jig to route off the small step to get it flush with the top of the body. It fits well now and when I’ve glued the neck in, I’ll fill in all the gaps and holes, epoxy maybe. Then I’ll use some high build 2K primer paint to cover the joint. This is another experiment so if it doesn’t work or cracks the paint over time, then I will post the results here so others can see and learn from it.

Make guitars, not war 🌍✌️🎸

I also did a spot of painting some cavities with shielding paint. It’s good stuff and will go a long way. About 3 coats are needed apparently and 24hrs in between coats.

Make guitars, not war 🌍✌️🎸

About 3 coats are needed apparently and 24hrs in between coats.

Yeah those are the drawbacks to using paint however I’m willing to bet that you could speed up the drying time with a hair dryer or heat gun. Or maybe just 12 hours in between coats.

I’d check for continuity after two and see how it is. Still, I prefer paint to foil.

Though I’m curious as to why you chose to shield before finishing?

Practice on scrap...

Did some more work on this Bandsman today and I am reporting back about the Aquacoat clear grain filler I used. It is expensive but it goes a long way, I think it’s an amazing product. I just scraped it across the grain with an old credit card and it dried to the touch within a few minutes. By the time I had done the whole body and got back to where I started, that bit had dried. So I gave the whole thing a second coat, just to be sure. Today I sanded it back and I have to say that it sands better than any other grain filler I’ve ever used. It doesn’t smell and cleanup is very easy as it is water based. The only con I would give it is the price, it is more than a little steep but that is not going to put me off using it as my go-to product for grain filler going forward. Superb product in every way. 👍

Make guitars, not war 🌍✌️🎸

Though I’m curious as to why you chose to shield before finishing?

@mattbeels I saw a video of someone saying that it’s less messy painting the cavities first, instead of potentially spilling it on a newly finished paint job (it might have been Mark). When I’m painting this guitar, I’ll mask up the cavities so I don’t spray coloured paint and clear all over them. 👍

Make guitars, not war 🌍✌️🎸

Gotcha. It can be done either way and putting clear over it isn’t a problem. I’ve put it on several guitars that were already finished and it cleans up easily with a damp rag when it’s wet.

I’ve missed a couple spots here and there and it also comes off when dry, just needs more work and care.

Practice on scrap...

Gotcha. It can be done either way and putting clear over it isn’t a problem. I’ve put it on several guitars that were already finished and it cleans up easily with a damp rag when it’s wet.

I’ve missed a couple spots here and there and it also comes off when dry, just needs more work and care.

@mattbeels Good to know, this is the first time I’ve ever used it so to be honest I just wanted to try it without waiting for the paint job to be done. 🤣

I wondered if it would be better to let it soak into the bare wood instead of painting it over a paint job. I also didn’t want to sand the cavities to key the surface so the conductive paint would stick properly. It probably doesn’t matter but that’s just my way of thinking. 🤘😁🤘🎸

Make guitars, not war 🌍✌️🎸

I never had a problem with it not sticking, the 'hardest' part is the long drying time and getting enough coats for good continuity.

I prefer to screw a (pre-wired) metal tab in the cavity and slather the paint all over that and connect it to the common ground.

It’s funny how a lot of factory guitars will hastily slap on a thin coat and then not even bother to connect it, wouldn’t matter if they did of course but still.

A silly waste...

Practice on scrap...

I prefer to screw a (pre-wired) metal tab in the cavity and slather the paint all over that and connect it to the common ground.

@mattbeels I don’t know how to do this but it sounds like a good idea.

Make guitars, not war 🌍✌️🎸

cover that connection with shielding paint and solder the wire to ground, easy peesy.

@mattbeels When you say solder to ground, do you mean to the back of the volume pot?

Make guitars, not war 🌍✌️🎸