Just beginning and making baby steps. Before you look at what I have, yes this is my first build and no I'm not making a bandsman. Not that I have anything against Mark's design. I'm just not sure if I'll be making more than this one (hopefully I will, though) and if I do only one I wanted it to be my own design. Although I still could change my mind and set this one aside for later. Anyway, the jigs, humbucker pattern, neck taper, and fretboard caul are all done and ready to go. I'm holding off on the neck pocket pattern until the neck is made.

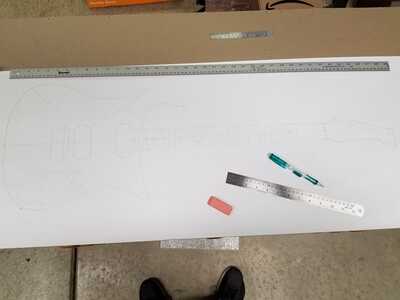

Here is the drawing. The control cavity probably looks a little odd but of course that can easily be changed. The main reason that I'm making an in-line headstock is because I have an in-line set of tuners from a guitar that I upgraded a year ago and I'd rather put those to use than buy a set of 3x3. Only problem with that is with the extra length needed for the headstock your typical 2" neck blank isn't long enough (stew mac only sells them at 26" long). This design calls for 28" minimum if it's going to be set. I have a body blank and a slotted fretboard but no neck blank yet. Maybe I should go with a bolt-on neck since 1" blanks come in longer sizes.

What do you guys think?

Hey @wayne_f. I really like the drawing and I like the headstock. Looks like you are all ready to start making saw dust. I'm in eastern canada and could not justify the cost of stewmac for most stuff. I have been ordering from a supplier in British Columbia, canada. They have had a really decent variety of woods for all types of builds that I have seen including neck blanks. That is where I order the neck blank from for the build I'm on. Their website is https://www.woodtoworks.com/. You should check them out. I don't know how much shipping would be for you but it is worth a look. They have been a fantastic company to deal with. I had a error/issue with one shipment and they fixed it super quick. They are just a great company to deal with so far.

Maybe I should go with a bolt-on neck since 1" blanks come in longer sizes.

Hi @wayne_f You should be able to ask for a longer blank, no matter who your wood supplier is. Just ask 😉

I think you would need to have a bit of a redesign around the neck pocket area if you want to convert to a bolt on (to add some sideways support).

I d rather stick to the design and ask for a longer blank if it was me.

You're off to a good start there! 👍

I think you would need to have a bit of a redesign around the neck pocket area if you want to convert to a bolt on (to add some sideways support).

@koendb True but it wouldn't be much of a problem. I guess I'll shop around more and possibly ask for a longer blank like you suggested.

Youve made a great start there, looks like you're very organised and methodical, thats a good way to work. On my first guitar, I kind of made it up as I went along, making templates and jigs as I needed them. If you're just going to build one, then as the other guys have said; probably best to get a longer blank to build what you want. Once you've finished the first one you will want to make just one more, so you'll still have you're neck blank for a set neck.

looks like you're very organised and methodical

@robin yeah, kinda. Although, since I am new to this I was a bit scatterbrained here and there. I screwed up a few times when making the jigs like forgetting to make sure all surfaces are flat and level, using a couple of screws that may have been a bit too big and split the MDF, and forgetting to measure the distance between the nut and scale length lines on the neck taper. I now have an extra neck taper that could be used for a 28" scale length 🙄 .

Can I ask how you managed to make an accurate neck taper template?

@russ I started with one straight edge on the MDF, as per Mark's instruction, cut a piece that was more than long enough and 60mm wide and then measured in from the good edge for the end lines. Then I took it to my bandsaw and slowly cut it as close to the line as possible. Then took a block with some 80 grit to sand it right down to the line. And, of course, checked it with a straightedge to make sure there were no high or low spots.

Can I ask how you managed to make an accurate neck taper template?

@russ not sure about others but I used a table saw with a jig I use to square rough planks. Happy to elaborate with picture if it’s of use?

…on an elaborate journey to turn trees into music.

Here’s a pic of one that does the same, I’ll post a pic of my more rough and ready version later. It’s basically a straight plank with a couple of clamps on, I might have over sold it 🙂 So you clamp you’re taper template wood on, cut one edge flat, draw on the taper as per marks instructions line that up with the edge of the jig and run the jig against the fence to keep it straight. Obviously you could use a band saw with a wide blade with a high tooth count and make the cut slow and you’d end up with a pretty good finish.

Hope that makes sense!

My version is a piece of MDF with a couple of cheap toggle clamps from Amazon screwed into it 😬

…on an elaborate journey to turn trees into music.

Currently waiting for my neck blank to be delivered but it should be here in a couple days. I ordered one that's 30X4X4. I'm gonna have to rip it down to two separate 2X4 pieces and then smooth out the ripped surfaces. That's the only way I could get one with a 4" quartersawn width. Every place that sells neck blanks cuts them with a maximum quartersawn width of 3". I emailed stew mac and asked if they could do a custom order cut but unfortunately they don't do that. I ultimately ended up ordering from exoticwoodzone.com

The next thing I need to work on before doing anything else is making the extended router base. The acrylic sheet has been sitting in my shed for the past 3 weeks and waiting to be shaped and drilled. I'm not gonna cut it into a big circle- just round off the corners so they won't be dangerous. I made my own corner radius router template for this particular job.

@robin Yep, that's the plan. Yesterday I also corrected the guide fence on my band saw by shimming one edge of the locking bar with some masking tape. I'll do a test cut on some scrap to make sure it's sitting truly straight. Then I'll throw a new blade on there and split the blank. Wish me luck just in case.