Hi "Chaps",

I'm planning a through-neck ("mahogany") Strat in lots of ways just because...

Using standard Strat hardware (tremulated) I'd be interested to know whether anyone can think of a reason why I need to engineer an angle on the neck?

(No scratchplate, pups loaded from the rear, angled headstock, 24.75" scale, 5 way rotary, single volume, no tone control.)

Cheers

Herb

Just posted 'How to make a Thru neck Electric Guitar'

https://guitarmaking.co.uk/community/annoucements/how-to-make-a-thru-neck-electric-guitar/#post-697

I'll mark this Q as closed - let me know if that is not the case 🙂

Cheers Herb

You will likely need a small neck angle to ensure the strings arrive at the right height for the bridge - failure to do this will mean you are stuck with really high action. It is not too difficult unless you are also planning a cap.

I can guide you through the tricky bits.

When you have finished your drawing post it here or send it to me and I will sort out a build plan for you.

Measure twice, cut once...

FYI: One alternative to a neck angle is to recess the bridge...but it is a bit of a cop out and you may have trouble fitting pickups/surrounds under the strings as they will be lower than normal. Not recommended.

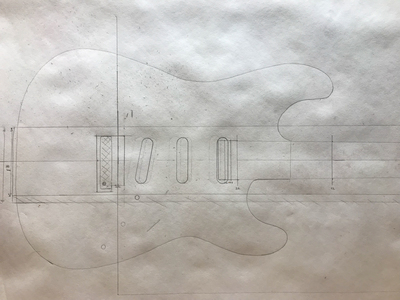

Now I have your lovely piece of rosewood I have begun the drawing and more detailed planning... I can now see that a conventional Strat not only has the fb thickness but also up to 5mm of neck wood when it arrives at the body which won't be present with a through-neck so an angle is required deffo.

Futhermore I notice that by moving pups 1 and 2 a few mm towards the bridge I could use all 24 frets that you've cut which would be much easier to access on a through-neck. Goodness knows what happens up there at the dusty end though.

Thanks for the kind offer... I'll double check with you when I have a plan.

Hah - the plan is to have no pup surrounds but to load from the rear. No screws on the front at all. Mad (probably) - but I think I have a plan.

I may not have enough neck depth to angle the headstock now I have to angle the neck - not a problem though.

Still need to source wood for the body wings but there's planning and routing to do before I need that.

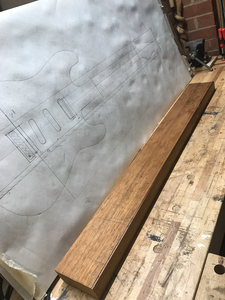

My block is 970x110x42

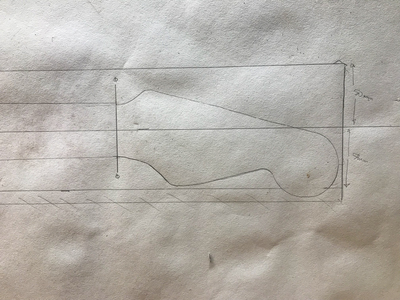

This is a first draft and I will re-draw when I have the actual components. I have used your fingerboard so that sets the length dimensions.

the controls are roughly where they are on a standard Strat, only the volume pot will be standard. Haven't decided about the output jack yet.

Very open to anyone's recommendations re pups (the contruction may make this warmer than a std Strat plus I use classic tones a lot with not a lot of drive), trem and light weight tuners.

Oh dear...! 42mm is too thin for a thru neck with a trem (unless you find one with a very small block)

Remember the 'neck angle' is actually cut into the body so it will inevitably come out thinner than your 42mm.

Most trem blocks are about 42mm long so it will stick out the back of the body...

Adding a cap to the front will not help as you are adding material to the wrong side (thus negating the 'Neck Angle')

One solution: To make the body thicker you can add material to the back of the body before you glue the body wings on.

My advice: Stick with a strat style fixed bridge - then you just have a slightly thinner body than normal (who's gonna complain about that 🙂

Let me know what you decide and I'll write up the order of events ...

Most of the jobs are the same but there are 2 major differences:

- Making the Neck Angle

- Gluing the Body Wings

Measure twice, cut once...

Ah! Not having the hardware yet I hadn't measured the depth of the trem block.

Back to the drawing board!

I had also been watching video of people putting the angle into the neck rather than the body but it sounds like you don't think that's good.

Having a whammy is important to me so I'll maybe use this block for a different project and source a deeper blank...

Can't progress anyway until I can afford the hardware...

Thinks... Hey but Mark... as I intend to spray said Stratomonster a Stratty colour I can attach a similar block underneath at the body end to the optimum thickness wot wot wot?

So you did Mark - I couldn't see through the tears of disappointment ?

This is the way we shall progress... thanks again for your patience.

Mark... I assume 70mm will be more than adequate at the body end?

I have a piece of mahogany I can glue on to give me that depth.

Were you going to instruct me on the order of events to make the neck angle?

Hey Herb -

If I buy laminates for thru necks they normally come 60-65mm - that is plenty.

We are making a thru neck bass right now so I took some video to try and explain the neck angle method -

You could do a side drawing to work it out - could be the subject of another video.

I'll see what I can do this week for ya - hold tight!

Measure twice, cut once...

I'm still thinking about this.

I think Fender Strats have no neck angle... Mine doesn't seem to.

Help me understand why I ought to engineer a small angle if I'm using standard fendery parts. Perhaps the height of the fretboard alone isn't sufficient?

Cheers

Perhaps the height of the fretboard alone isn't sufficient?

Yes Herb - you have answered your own question! ?

On a Strat (or any other bolt on neck) the neck sticks out enough so that the strings arrive at the right height. No angle necessary.

On a thru neck you will need the angle.

Incidentally - this is why you rarely see a Tune-o-matic bridge on a thru neck. TOM are much higher and require a bigger angle - so you need to start with a deeper blank making it more expensive (and more waste).

Measure twice, cut once...

My calculations indicate a drop of about 4mm from the end of the fingerboard to the (Wilkinson trem) bridge. About 2 to 2.5 deg. Does that sound about right?

Intend about 9 deg headstock angle too?

Sounds perfect Herb - I took some video of the process during the last course - Will try to edit/upload something ASAP.

Measure twice, cut once...

Jolly good, thanks Mark.

Cut the truss rod slot and angled the headstock this afternoon. Now, we're away for a week then it's back to the prototype piece figuring out the pup mounting on a plate from behind whilst anchoring the trem springs. Soon I'll need wood for the wings... totally absorbing ain't it.