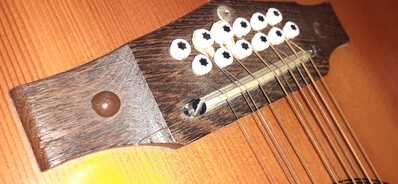

My daughter's friend's dad has had this EKO 12 string acoustic since 1976 and it's been in its case in is attic for the last 30 years. He dug it out recently and wants to play again. When he went to restring it he noticed a crack in the bridge. So to cut along story short, it's landed with me to repair it.

The bridge appears to be pop riveted on rather than glued. So I'm thinking just remove the saddle and fill the crack with superglue and clamp it closed. Any advice before I dive in.

He's also asked me to remove name label which look like self adhesive aluminium plates. I'm a bit reluctant to do it, I don't know what kind of mess that would leave. But he wants me to try, worst case is to glue the labels back on again. I was thinking of heating it to soften the glue, but how much heat can I apply without doing any damage.

I'd be very wary of trying to remove the JOE label.

Danger of damaging (splitting) the top of the guitar - you don't know how dry it's become after 30 years in a case in the attic - plus I'd have thought that the finish underneath the label is more or less guaranteed to be damaged.

Maybe stick something else more appropriate over the top of it if he's changed his name ....

Online guitar making courses – guitarmaking.co.uk

The bridge appears to be pop riveted on rather than glued. So I'm thinking just remove the saddle and fill the crack with superglue and clamp it closed. Any advice before I dive in.

I'd say be careful that, in trying to squeeze the top of the bridge plate together, you don't pull the base of the bridge away from the top of the guitar. Other than that, a fill & glue repair looks best.

Does the split extend into/along the saddle slot at all, or is it just at the end that you can see in the photo? Possibly just from the wood drying out over the time it's been in the loft rather than anything structurally nasty.

🙂

Online guitar making courses – guitarmaking.co.uk

He's also asked me to remove name label which look like self adhesive aluminium plates

Hi @robin

I saw this stuff from Stewmac.

🙂🎶🙏🎸

🗝️ "Life's what you make it"🗝️

I agree with @tv101 removing the name label will leave a worse mess and the wood underneath will be a lighter colour as sound boards darken with exposure to UV light when the instrument is out of the case.

My guess is that the labels are aluminium foil with a self adhesive backing which has probably started to fail over time. So I would try peeling one corner of the foil using a chisel with the bevel side down, or even a credit card which won’t damage the finish. If you can remove the foil then the adhesive will rub off with careful application of methylated spirit. The finish can be polished after that.

The pop rivet on the bridge looks like a DIY fix. Under the two wooden (plastic maybe) domes will be bolts which you can feel by putting your hand inside the sound hole. I would mix up glue and sawdust to fill the crack but I actually don’t think it’s too big a problem unless the bridge is lifting anywhere. I wouldn’t try squeezing the crack unless it’s separated from the soundboard.

Some people call me a tool, others are less complimentary. Tools being useful things.

Thanks to you all for the advice guys, I did point out the risks in removing the label but Joe (he hasn't changed his name) wants me to try. It's three separate alum plates about 1.5mm thick, so cant just scrape them off.

As for the bridge, pop rivets seem to be the standard construction for this model. I haven't taken the saddle off yet, but I think I can see the beginning of a crack at the other end.

He's also given me a banjo that needs a bit of attention, obviously I'll not be asking advice on that as I've already anticipated the answer.

If the plates are 1.5mm thick then I would put some protection on the soundboard, like thick plastic and lever them off with a chisel. Old adhesive shouldn’t be that strong to resist very much. Words fail me for pop rivets.

Ive done a few banjo repairs and do have an Irish tenor banjo so if you want to run the problem past me I might have a solution. They are not nearly as complicated as guitars.

Some people call me a tool, others are less complimentary. Tools being useful things.

He's also given me a banjo that needs a bit of attention, obviously I'll not be asking advice on that as I've already anticipated the answer.

As I don't like to be too predictable, I thought I'd see if I could offer some useful tips for banjo repair.

After all, they get a lot of grief, but a banjo is still an instrument. It's not the banjo's fault! And I'd hate to think of a banjo, sat in a corner, unloved and just in need of some appropriate attention.

🙂

So, I googled "banjo repair kit" to check out what's currently recommended.

Hope this helps.

👍

Online guitar making courses – guitarmaking.co.uk

Ive done a few banjo repairs and do have an Irish tenor banjo so if you want to run the problem past me I might have a solution. They are not nearly as complicated as guitars.

On the banjo, it looks like its been put away with a bit of dampness on two of the tuners. There basic open gear type and seized up with green verdigris. I've got them cleaned up an free now, but two retaining screws were rusted and the heads broke off when I tried to remove them. I've made my little hollow drill to extract them with and will plug the holes. At a quick look, the string action looks about half an inch, that'll need further investigation.

Time for some allergy therapy, go on you know you want to. They can be black.

@rocknroller912 Acoustic guitars are too complex for my tiny little brain, I only do solid chunks of wood. 🤣

Make guitars, not war 🌍✌️🎸

If the banjo has a makers name it’s a good idea to google check it first in case it’s a valuable antique.

The string action sounds high and reasons for this could be:

1. the neck angle to the body is incorrect or the neck is set too high on the body. A lot of cheaper banjos are just badly made but some have an oval slot in the body to adjust the height up or down. If you can adjust it and there is a gap then a piece of thick felt or green baize is fitted between wood and metal. If there is no adjusting slot you can enlarge the fixing hole with a file.

2. The bridge is too high although this is unlikely and I’ve not seen one.

3. the bridge is too far forward and the placement is the same as for guitars, 12th fret to bridge is the same as the measurement from nut to 12th fret plus a little bit extra. Easy enough to check with a tuner.

Also is the banjo head plastic or natural skin. This makes a difference to how much tension you can get on the head and skins will always have a sag.

Another important thing is not to overtighten the rim rod which runs inside the body from the neck to the tailpiece as this will pull the body out of its round shape. It might be a piece of wood with no adjustment rather than metal.

Some people call me a tool, others are less complimentary. Tools being useful things.

Thanks for all that information, I don't see any name on the banjo at all. I'm waiting for screws to arrive to put the tuners back on, then I'll have another look at it.

Can you post a photo of the banjo where the neck and body are joined. I’m thinking you might need to carve some wood from the neck to get it higher up and improve the action. Altering the neck angle can be a nightmare as it would be carving a complex curve into end grain. My advice is don’t try.

Some people call me a tool, others are less complimentary. Tools being useful things.

You've preempted the questions I was going to ask you and I'd already taken this photo before I saw your post. The string height at the 12 fret is about 5mm and looks about 1.5mm relief at the 7th fret. My first thought was that it looks like the neck angle needs adjusted as there's no room for movement either up or down without carving a bit out of the neck or body.

My preference would be to cut away some wood from where the bottom of the head butts against the neck and move the whole thing up, but there is a lot of string height to take up. Changing the neck angle will need templates of the body and resonator curves and a lot of fitting to the neck. It might be easier to remove the fretboard and fit a long wedge under it. Seems unplayable at the moment.

Tried to save the photos to draw on them with an apple pencil to demonstrate but it won’t let me. How much can you remove from the bridge to lower the string height ? Maybe try a wood scrap to get an idea.

Some people call me a tool, others are less complimentary. Tools being useful things.