Nice work there @darrenking, I'm envious of the precision of your CNC routing, I used to programme CNC sheet metal punching machines and plasma cutters many years ago, but that was only two dimensional stuff. I'm also curious about the threaded inserts for your control cover, I can only imagine that you've done that just because you can.

...have been wound on the thighs of virgin mermaids...

I like your style but, do mermaids even have thighs? 🤔

Though, tbh, if you want jazzy because you'll be playing jazz, it doesn't really matter which pickups you use or what they sound like ...

... no-one will be listening

😂😂😂

Practice on scrap...

I like your style but, do mermaids even have thighs?

@mattbeels and @tv101 Yes, one big thigh but it’s a bit weird fantasising about virgin aquatic species. 🧜♀️

Make guitars, not war 🌍✌️🎸

just because you can.

Yes, pretty much Robin, I wanted to use little M3 stainless hex socket machine screws for the fixings rather than wood screws and the inserts grip pretty well once the screw is in position.

I'm envious of the precision of your CNC routing

Yes, some of my most accurate cock ups ever have been achieved using my CNC router!!

I'm envious of the precision of your CNC routing

Yes, some of my most accurate cock ups ever have been achieved using my CNC router!!

There's plenty of envy here too - but I also recognise that the "measure twice, cut once" principle still applies. There also seems to be a lot more potential for cock up, because you're telling a machine to do something, and a machine will just get on and do it.

At least if you're doing it yourself, there's a chance you may just spot something, think "that's not quite right" and stop before you've completely wrecked the workpiece.

That said, once you've got the files that you know are right, just keep pressing go ...

Online guitar making courses – guitarmaking.co.uk

just because you can.

Yes, pretty much Robin, I wanted to use little M3 stainless hex socket machine screws for the fixings rather than wood screws and the inserts grip pretty well once the screw is in position.

I think there's a genuine use-case benefit.

The cavity cover is probably the most removed/replaced part of the guitar. A small screw into a piece of wood, is only going to retain its thread so many times. The captive nut & machine screw will give a better connection for much longer.

👍

Online guitar making courses – guitarmaking.co.uk

^^^^ That would take me months - and then they'd all be different!!

Online guitar making courses – guitarmaking.co.uk

You mean like this.....

@darren Looking good Darren, that’s the way to pump them out.

Make guitars, not war 🌍✌️🎸

That would take me months - and then they'd all be different!!

@tv101 Yeah me too but we get to put all of our signature mistakes (I mean makers’ marks) on them. 😁👍

Make guitars, not war 🌍✌️🎸

@darrenking. Very nicely done Darren. I'm well impressed with your engineering and design skills. I do love a bit of precision workmanship.

🙂🎶🙏🎸

🗝️ "Life's what you make it"🗝️

Unfortunately my mouse broke down so I had to take a break from work and fit the neck of my electric Maccaferri whilst the mouse was charging.

Don't worry, I left some gaps in the joint from the front, but my phone just can't seem to focus on them properly for some reason!

Given that this neck would be pretty much impossible to remove regardless of which adhesive I use to stick it on, is there any reason not to use epoxy?

🗝️ "Life's what you make it"🗝️

Thanks Russ,

And I would like to point out that this bit was done by hand! 🙂 🙂

is there any reason not to use epoxy?

I'm not sure that epoxy counts as a "tone glue".

Why wouldn't you use good old favourite Titebond? If it's good enough for the boss ...

And you should leave your mouse unplugged more often!

Online guitar making courses – guitarmaking.co.uk

And I would like to point out that this bit was done by hand! 🙂 🙂

Very Impressive. 👍

🙏🎸🙂🎶

🗝️ "Life's what you make it"🗝️

I have too many guitars...said no one in the world..ever!

Er, yeah, and this was done by hand too!! Not quite sure what happened but the central spur was not at all keen to stay on course in the mainly end grain of this part of the body.

So, after much swearing and blasphemy, a plan was hatched! Thinks ‘Rio rosewood insert’ thereby, not only resolving the immediate issue but also preventing me from ever being able to sell the guitar in the future! TV, I know you’ll be proud of me and, once completed, my wife will be half way to another puppy!

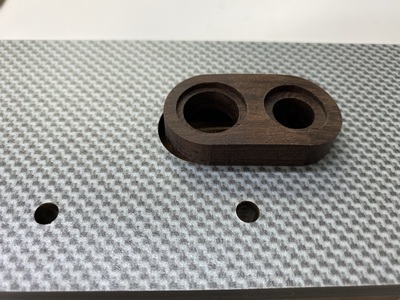

Holding small bits of material on the router requires a mask to be cut into 3mm sealed MDF into which the wood blank to be machined can be held by vacuum. The small inserts themselves are also held within the waste material with 10mm x 1mm thick tabs. These are easy to cut through by hand afterwards but they stop the component detaching during machining and flying across the workshop or, worse, causing a broken cutter.

The next thing was to machine the template that I will use to machine the recess into the body

I then shaped the insert a little by hand to ensure that the kill switch and cable sockets were still recessed sufficiently once the insert was shaped to match the contour of the body.

Looking good I think, and another great example of design by necessity!! Just don’t tell anyone, it might end up being a £150 option! 🤣 🤣 🤣

I’ll post pics of the completed body machining template, the machining itself and the fitted insert by the weekend.

Cheers and hope see you tomorrow in the love stream.

Darren