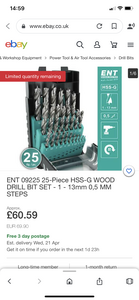

Here ya go, duty free. Probably available at Amazon as well. These, of course are not the be all, end all of drill bits but they are great quality and I can recommend them. There are other excellent brands, you just need to look at similarly priced items. This set has several sizes not needed for guitar building but you’ll usually find that it’s either a full set or a small one that’s missing two sizes that you need. Having a comprehensive set is nice for any project that comes your way. Keep in mind that the bits from 10.5 and above will most likely not fit in your hand drill. There are bits that size with a reduced shaft in you need them otherwise they’ll typically fit your drill press as I believe 16mm capacity is standard. Plus, if you’ll be using any American made bridges for example you’ll need the imperial sized bit for the posts ie tune o matic/wraparound style.

Practice on scrap...

Here ya go, duty free. Probably available at Amazon as well.

Was there meant to be a link or a photo attached @mattbeels? 🤔

🙂🎶🎸🙏

🗝️ "Life's what you make it"🗝️

if you’ll be using any American made bridges for example you’ll need the imperial sized bit for the posts ie tune o matic/wraparound style.

@mattbeels Yeah they are a pain. 🤘😝🤘🎸

Make guitars, not war 🌍✌️🎸

@Russ - I got the first drill-perpendicular-holes gadget that you posted, and a variation on the second version.

They work in some situations/positions, but won't work in all. The main problem is ensuring that the guide fits flat on the piece you're drilling into, and in the correct position, and doesn't move when you get the drill bit inserted and drilling.

I don't think there's a serious problem with wear - on either the guides or the bits - because you're only going to be using them infrequently. Plus, once you've got the first couple of cms of the hole drilled, you can remove the guide and drill straight into the hole (assuming you want it deeper than a couple of cms) as the initial cms of the hole will keep the bit straight as you drill the rest.

Online guitar making courses – guitarmaking.co.uk

drill bits for wood?

These are lovely. Yes they're expensive, but I'm not sorry I spent the money.

https://www.workshopheaven.com/star-m-japanese-601-precision-drills-set-of-16-in-a-canvas-roll.html

Has anyone ever used one of these to drill a straight hole? Are they accurate?

@russ I’ve a set of those, came from axeminster I think. They’re ok, trouble is keeping them steady at first, where they were most use was drilling into a corner edge or through dowel. It’d be better if they made the baseplate wider so you could clamp it really.

…on an elaborate journey to turn trees into music.

@russ I’ve a set of those, came from axeminster I think. They’re ok, trouble is keeping them steady at first, where they were most use was drilling into a corner edge or through dowel. It’d be better if they made the baseplate wider so you could clamp it really.

Cheers @tej. Thanks for the advice.

🙂🎶🎸🙏

🗝️ "Life's what you make it"🗝️

Those bits do indeed look lovely @jonhodgson! I wanted bits like those with the posi-drive or whatever it’s called, but the set I found when shopping was quite small. I do own some Japanese tools and they always deliver.

Practice on scrap...

@russ, so I tried it out on a scrap of pine with a 10mm Brad point, a couple of points right away. Firstly the guide doesn’t fit perfectly snug in the plastic holder. Secondly when it’s in there and you have the drill bit this means that even with the plate flat you have about 1mm of play in any direction. So instantly your hole isn’t going to be perfect. When drilling the guide actually starts to come out of the holder as the chips are carried up by the flutes.

So I pushed a section of 10mm steel tube through the 45mm hole and at 30mm above the wood there was about 0.25mm gap between the tube and the edge of a square. I’d say that give the height of the bridge mounts this would probably be acceptable and for the machine heads as they’re in much thinner stock and effectively clamped both sides that it would be ok for that too.

To be clear though even my previously slated and since reprieved Aldi pillar drill did a better job and I think that was only about £65 when I got it.

If you get a set then absolutely do a few test runs on maple/mahogany first though as appreciate my pine isn’t a perfect test piece.

…on an elaborate journey to turn trees into music.

@russ I think that’s the better plan, they’re useful for a lot of tasks. Just please check the distance into the piece the one you get will cut, mine didn’t have clearance to drill the string holes and bridge mounts for a Tele style body. I sadly have to have most bench tools mounted to ply bases that I swap out onto a workmate, I don’t think you’d get away with this with a “proper” size pillar drill.

…on an elaborate journey to turn trees into music.

or just keep saving for a pillar drill.

By the time you add up the cash that you spend on alternatives that aren't quite up to the job ... the pillar drill might look less expensive.

Or keep your eyes out for something s/h?

Or, as Mark often says, just tell everyone-you-know that you're looking for one, and you never know who might have one unused in the back of a shed, or still in use, but they'd be happy for you to use it occasionally.

Online guitar making courses – guitarmaking.co.uk

Or keep your eyes out for something s/h?

@tv101 Do you know of any particular drills worth looking out for s/h? Would like to get hold of a bigger/better one for when I get more workshop space, sometime in the next 10 years 😬 There is a lot of rubbish out there it’s hard to see what might actually be worth pursuing.

…on an elaborate journey to turn trees into music.