I think the general rule for s/h kit is "older is better". More modern tools are made down to a price (apart from those brands that can charge the price for maintaining quality) because so many of us want something that's "a bargain".

Some of the old (60's/70's) British-made tools were engineered to a quality standard, and can generally be repaired when parts do wear out. Although those can also be collectible and so attract collector's prices. Gumtree or car boots might be a source - eg where someone is clearing out Grandad's old workshop - or word of mouth if you ask around friends, friends of friends, neighbours, etc.

More generally, Axminster brand seem to be OK and are reasonably commonplace, so you'll probably find those appearing on eBay too, though once it gets onto the eBay marketplace, prices can be higher.

Drill presses aren't complicated bits of kit. If something does go wrong, or break, then if you're handy with some metalworking - or know someone who is - then repairs should be possible. Buying something broken-but-viably-repairable could be an option too.

Online guitar making courses – guitarmaking.co.uk

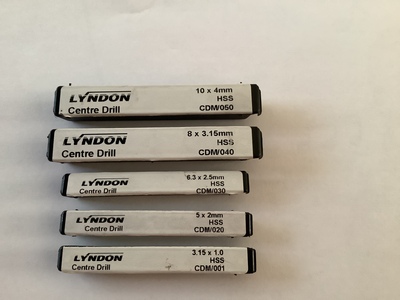

I don’t know if people have seen these before, it’s what I use to make accurately positioned holes. It took me a while to find them so I’m a bit behind the discussion. They are mostly a metalwork bit designed for use in drill press or lathe where the pressure needed to make a mark in metal distorts the bit and makes it slide off where it’s supposed to be. Can be used as a pilot hole to be enlarged with bigger sizes.

The fat shank and short point give a very good result and no run out even higher speeds. They work well in wood and don’t follow the grain like longer bits do. Should be ok with the drill guides that were posted earlier due to the smooth shank.Various sizes are available that’s just the selection I bought for the jobs I needed to do.

Some people call me a tool, others are less complimentary. Tools being useful things.

@rocknroller912, those are centre drills, their job is really to create a countersunk hole for a lathe centre. What you're describing (functionally speaking) is a spot drill, they're what you're supposed to use start an accurate hole in machining.

Some people call me a tool, others are less complimentary. Tools being useful things.

Make guitars, not war 🌍✌️🎸

Working with wood, you're probably fine, especially as tolerances of 1/10th mm are probably plenty good enough.

If you're trying to place accurate holes in metal, where aside from the harder material you're probably talking about tolerances 10 times tighter (or more) it can matter, plus it can damage the cutting edge of the twist drill.

@cheesewhisk so from one of your images I can see you’ve used pins to locate the board as Mark suggests, what I don’t get is how that’s meant you didn’t get it located where you wanted it. Consensus seems to be too much glue and pressure, would you agree?

I’ve only ever glued one fretboard to a neck and for spreading glue used a plastic card to put the thinnest layer I could on, even then there was a lot of squeeze out. Not at all clear to me what the magic formula for this is!

…on an elaborate journey to turn trees into music.