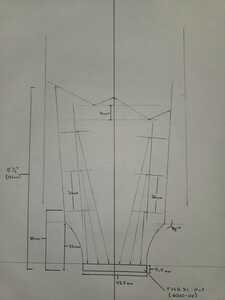

Getting started on this summer's guitar project. I'm still in the design phase right now but will probably be cutting some wood within the next couple weeks. All I have done so far is the headstock design but I do have an idea of how I want the whole guitar to look. I'm considering doing a trem bridge this time around. Anyway, here's the headstock. What do you guys think?

What do you guys think?

It's a nice shape @wayne_f . It's a bit wide for my personal preference, I like to taper it in towords the end rather than out. That keeps the strings straighter beyond the nut, whether it makes any difference or not, I've no idea.

So long as the tuner posts don’t get in the way of the next string, from a practical point of view, it will do just fine.

The design is definitely different and I like that. It’s unusual and perhaps not to everyone’s taste but what is? Everything is subjective, so different and unusual design is encouraged, certainly by me.

Beauty is in the eye of the beholder.

Go for it @wayne_f

Make guitars, not war 🌍✌️🎸

Yeah, I expected the angle to be the main criticism. It's my take on the Dean style 3X3 design which they use for almost half of their catalog. I swear there was another brand that did this as well but I can't think of who it was. Oh, well. This should be fine but if any little issues pop up then a redesign will be in the works. I'm considering this to be a prototype.

@russ Haha really? I don't see it.

Hi @wayne_f I tend to agree about the angle of the string from the nut to the tuner due to the wide headstock. If there is too much friction on the string in the nut slot this can make tuning, and staying in tune, a real pain, especially if you like bending your strings. If you are making you own nut you can compensate for this by cutting the slots at an angle so that the deviation is split thereby reducing the resistance on the strings movement. Good luck with your build, it certainly looks like its going to have ‘attitude’!

CHeers

Darren

Okay, finally posting some progress. Even though the project is just starting I've already made a couple mistakes. Fortunately those mistakes are not difficult to work around. First, I accidentally cut the truss rod slot a little too deep. That was easily fixed by surface routing the extra 2mm off of the top of the blank. Then, when cutting the headstock angle on the bandsaw, I went a little too close to the line leaving me very little room for routing. By the time I realized the angle wasn't meeting the nut line evenly there was almost no more material left to remove. This was corrected by repositioning the blank in the jig, adjusting the router and starting from the high side.

So with those problems behind me, yesterday I got the fretboard tapered and the neck shape cut out. Today, I'll be thicknessing the headstock, profiling the neck and drilling tuner holes. Possibly more if I have time.

Just got done out in the workshop a couple hours ago and I've run into another problem. I might need to scrap this and start over. After routing the profile of the neck I noticed that the truss rod slot looked a little off. The template must have been off center. Now it seems like the neck is a little too narrow at the nut end.

After routing the profile of the neck I noticed that the truss rod slot looked a little off. The template must have been off center. Now it seems like the neck is a little too narrow at the nut end.

@wayne_f How about making the fretboard to the width that you want and then blend/taper it in at fretboard/neck/nut joint line.

I think Mark did a video on how to route a truss rod slot after the neck has been profiled. Search through the utube videos I’m sure you will find it. You could glue a veneer shim on the short side and cut the channel again.

If the neck is too narrow then Robin’s suggestion of a wider fretboard tapered will work. I’ve used it on older violins a few times to save replacing the whole neck.

Some people call me a tool, others are less complimentary. Tools being useful things.

Just got done out in the workshop a couple hours ago and I've run into another problem. I might need to scrap this and start over. After routing the profile of the neck I noticed that the truss rod slot looked a little off. The template must have been off center. Now it seems like the neck is a little too narrow at the nut end.

@wayne_f If the truss rod is slightly off centre, I wouldn’t think that is a problem, just leave it. I would line up the nut with the centre line and carry on. If the you feel the neck is too narrow at the nut, use a smaller nut and a narrower string spacing.

Measure the width of the neck at the nut with your callipers, then set them to half that distance and measure from either side to see how close it is to the centre line.

Another option is to fill the truss rod route with a fillet (glued in) then reroute the slot. There is a YouTube video that Mark made showing how to do this, I’ll have a look for it.

Make guitars, not war 🌍✌️🎸

@robin I've compared the neck to the fretboard and the board is a bit wider. Your suggestion of blending the joint while carving sounds much better than scrapping the whole thing. After my last post I relaxed a bit and reminded myself that this is only going to be a prototype anyway. I'd be much more worried if I were making this for someone else.