What’s the difference? I always thought they were two names for the same thing and a quick goofle search seems to confirm that...

@mattbeels I’ve no idea it just wasn’t clear! I’ll watch that video though as there are a few types I’ve seen that I’m curious about.

…on an elaborate journey to turn trees into music.

Here we go 🙂 This is the truss rod I have which gets quite big at one end:

@markbailey, or anyone else for that matter! The video lesson says that tightening it should make the centre of the rod arch up which with it this way round it does, with the flat edge of the rod facing the fretboard. The main bit of the rod is 9.3mm deep so I’ll route most of the channel to 10.8mm to give room for the 1.5mm fillet later. The end with the adjuster is another 1.7mm lower than the rest of the rod (and wider as per my other message) so was just going to route that end deeper. Will this still be accessible to adjust or will I need to extend the slot further than 20mm from the centre of the nut? Hope this makes sense as I appreciate it’s a bit rambly!!!

…on an elaborate journey to turn trees into music.

Opted to do a test on scrap, now have half a beautiful pine neck. It’ll be on eBay soon, don’t all rush at once. 20mm is a little tight so gonna add another half on. Rod was actually 9mm with callipers so most of it is routed to 10.5mm and the bit for the adjuster is at 12.5mm depth with the wider bit. Used the neck angle jig to simulate the angle from the back of the nut. I’ll breech the mahogany tomorrow 🙂

…on an elaborate journey to turn trees into music.

20mm is a little tight so gonna add another half on. Rod was actually 9mm with callipers so most of it is routed to 10.5mm and the bit for the adjuster is at 12.5mm depth with the wider bit. Used the neck angle jig to simulate the angle from the back of the nut. I’ll breech the mahogany tomorrow 🙂

@tej That’s fine mate, some are like that and you just have to route a little deeper, but not too deep. Careful now. It’s all good, keep going. 👍

Make guitars, not war 🌍✌️🎸

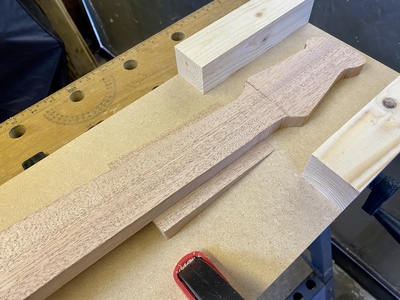

I’ve made a bit more progress now, fixed the sloping truss rod channel by routing to the lowest depth and glueing in a strip to the base of the slot. Angled the headstock, thicknesses it and rough cut the neck with no further mistakes. Surface routing is a very satisfying task!

…on an elaborate journey to turn trees into music.

I’ve made a bit more progress now, fixed the sloping truss rod channel by routing to the lowest depth and glueing in a strip to the base of the slot. Angled the headstock, thicknesses it and rough cut the neck with no further mistakes. Surface routing is a very satisfying task!

Looking good @tej how long are you leaving the tenon?

Make guitars, not war 🌍✌️🎸

@boo will have to check the design and get back to you. A lot shorter that you see on the picture. Need to make a template for that too actually. Progress stalled slightly as I realised I’d not made a taper template or fretboard caul so had to make those. Marked out the tuners now though so needy step should be swift. Still need a fret hammer and fret end nippers and can’t find a shop with them both at a sensible price and also in stock! There are a few places people have suggested at various points for me to check though.

…on an elaborate journey to turn trees into music.

Still need a fret hammer and fret end nippers and can’t find a shop with them both at a sensible price and also in stock! There are a few places people have suggested at various points for me to check though.

@tej These are decent and will last. Cheap ones are crap, they don’t last and will just frustrate you. This is quite reasonable actually.

https://tonetechluthiersupplies.co.uk/fret-cutter-end-nipper.html

Make guitars, not war 🌍✌️🎸

@tej I have one of these hammers too, they do the job nicely.

https://tonetechluthiersupplies.co.uk/summit-fretting-hammer-27mm.html

Make guitars, not war 🌍✌️🎸

Well it looks like I didn’t learn the lesson about not working on this when tired and I’ve managed to to not only mark out but then drill 2 tuner holes a whole 10mm out 🤬 short of laminating the headstock I don’t think there is a clean way out of this one?

…on an elaborate journey to turn trees into music.

Well it looks like I didn’t learn the lesson about not working on this when tired and I’ve managed to to not only mark out but then drill 2 tuner holes a whole 10mm out 🤬 short of laminating the headstock I don’t think there is a clean way out of this one?

@tej Not to worry, you’ll just have to either put a laminate over it (front and back or paint it. Either way you’ll have to plug the holes and redrill. Don’t worry about it, it’s not too much of a hassle.

Make guitars, not war 🌍✌️🎸

well.... you could make some dowels out of the off cuts when you cut the head stock out (so the color is the same) and glue them in to fill the holes. Then cut new holes. And then, if it was mine, I'd consider putting a headstock veneer on to cover the mistake from the front.

I think I’d rather laminate it than paint it for this build, I’ll have to find some nice wood to do that with as I’ve nothing I can use. I’m presuming this is “simply” a case of roughly cutting the laminate, drilling the holes in it, surface routing each face to the depth of the laminate, glueing it on and sanding it flush?

…on an elaborate journey to turn trees into music.

So the dowel cutters I have are utterly useless, at least two of you can guess where hey came from? 😉 Had to turn some on the trusty toy lathe.

Have some ebony and Indian rosewood veneers on the way, leaning toward the complete constraint of the ebony personally nut will make that call when they arrive. Now just need to modify the headstock angle jig with a block to support the now thicknessed neck so I can route out the rebate for he veneer. At least the back face will be easier though I’ll need to set a stop to give me a perfect line for the back veneer. What could possibly go wrong 😬

…on an elaborate journey to turn trees into music.

@jonhodgson Yeah I watched that video recently too, very cool idea, I’ll be making one. 👍

Make guitars, not war 🌍✌️🎸

After I’ve applied the veneers and got the edges level with the headstock is there any reason not to surface route the laminate? Ones I ordered are 2mm think and really only wanted 1mm.

…on an elaborate journey to turn trees into music.