Why wouldn't you use good old favourite Titebond?

I was thinking of epoxy’s superior structural gap filling qualities but you have shamed me into fixing the gaps in the front by stick a bit on veneer on either side of the front portion of the neck tenon. The fit is now such a wonderfully tight fit I am more than happy to use some yellow PVA to stick it on!

Now for a fretboard!

Cheers

Darren

To my eyes, that is just beautiful. It's beautiful as an object, as art, the fact that it's a functional object is an added bonus!

Clever man.

TV, I know you’ll be proud of me and, once completed, my wife will be half way to another puppy!

Proud - and envious of your design and CNC-programming skills! Brilliant work.

Didn't realise that you were operating under a similar guitars=puppies deal. I think we've got to the stage where I agree I've got enough guitars, and my wife agrees she has enough dogs! It was a bit like the arms race for a while though ...

😆

Online guitar making courses – guitarmaking.co.uk

To my eyes, that is just beautiful. It's beautiful as an object, as art, the fact that it's a functional object is an added bonus!

I agree with @tv101 are you gonna sell those @darrenking they are mint 🤩. I’d be up for buying some.

Most of the best things come out of mistakes and the kill switch for changing cables is just great..what a feature.

I have too many guitars...said no one in the world..ever!

I have too many guitars...said no one in the world..ever!

I need to change my signature now @TV101 🙄

I have too many guitars...said no one in the world..ever!

Online guitar making courses – guitarmaking.co.uk

I have too many guitars...said no one in the world..ever!

Is “too many” even possible?

Never.......🤣

I have too many guitars...said no one in the world..ever!

Didn't realise that you were operating under a similar guitars=puppies deal.

I made the mistake of mentioning it once and Dawn thought it was a VERY good idea!! In fact, she keeps encouraging me spend more time over at factory at weekends!

“enough”.

Just looked this up in the guitar makers dictionary and there is no entry for the word! Are you sure you’re spelling it correctly?

🤣

I have too many guitars...said no one in the world..ever!

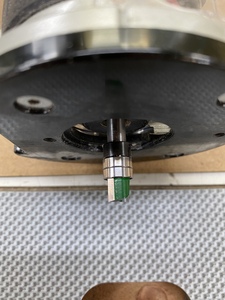

And I would like to point out that this bit was done by hand! 🙂 🙂

You certainly did an excellent job mating the neck to the body by hand, it looks awesome! The same goes for your jack/killswitch plate. Great fix!

Practice on scrap...

Ok, so here are the pics of the completed jig and the machining. I do love the little cordless Makita router. I wouldn’t try to machine full depth pick-up recesses with it but for operations that are beyond a Dremel it is a great next step. It has numerous bases including a full plunge system and I also use one on my binding router jig.

And here it is stuck in and sanded flush and with a bit of alcohol spray to make it look pretty.

@darrenking I’m loving that...get in your website or guitarmaking.co.uk

I have too many guitars...said no one in the world..ever!

And here it is stuck in and sanded flush and with a bit of alcohol spray to make it look pretty.

@darrenking That is pretty damn cool Darren, I want some. 👍

Make guitars, not war 🌍✌️🎸

And here it is stuck in and sanded flush and with a bit of alcohol spray to make it look pretty.

That jack plug insert is a touch of genius, and beautifully fitted in too.

I take it you are going with an oil finish?

I love oil finishes but I am just worried that the walnut has too many little surface deviations that would really benefit from a good dose of grain filler and a nice coat of lacquer. I have always loved a satin/matt finish on beautiful wood but I would really like to give my new mop polisher a run out on it! I can always flat it off again afterwards if it end up just looking too shiny!

That's quality.

Great piece of craftsmanship there. I might tease re the CNC'ing, but the CNC machine didn't put the recess into the body, or fit the insert flush with the edge of the body! Really nice work.

Whether you oil it, or lacquer it, you're still going to see the beauty of the grain.

👍

Online guitar making courses – guitarmaking.co.uk

That's quality.

Great piece of craftsmanship there. I might tease re the CNC'ing, but the CNC machine didn't put the recess into the body, or fit the insert flush with the edge of the body! Really nice work.

Whether you oil it, or lacquer it, you're still going to see the beauty of the grain.

👍

Online guitar making courses – guitarmaking.co.uk