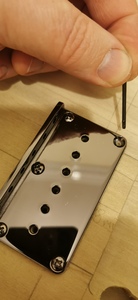

I snapped my 2mm drill bit off.

Any ideas?

I think I remember Mark doing this in one of the live streams when he was trying to drill a hole for a strap button. I think he might have used one of Carol's wind chimes to drill it out then refilled the hole.

🤔 🤨

🗝️ "Life's what you make it"🗝️

There are excellent videos on YouTube about how to do this.

Obviously the bridge requires removal.

If you contain operation/repairs, they will be hiden by bridge plate.

I'd probably shave wood /inner side of hole until tweezers/long nose pliers can grip bit.

Either fill where wood was removed or better would be drill and plug and redrill for screw

I've lost count of the 1mm - 2.5mm bits I've replaced over the years.

@russ and @eddie6string Yeah thanks for the reminder guys. I knew about this stuff in the back of my mind, although I had forgotten about the wind chimes. 🤣

This is one of those times when you just have to walk away and deal with it the day after. I did, however, use my guitar makers knife to carve the lower horn for fret access and I’ll finish it off with a small razor file and sandpaper.

Make guitars, not war 🌍✌️🎸

That f$$king sucks!!!

I have that “screw repair kit” or whatever stewmac calls it. You can make your own removal tool by cutting teeth into some brass or aluminum pipe, but I’m guessing that’s what’s known around here as Carol’s wind chime. (Best use for them if you ask me🤫😜)

Nice thing about the homemade version is that you can make different sizes as the stewmac version (while professional) is one size only. It was however designed for small screws.

Good luck dude!

Practice on scrap...

Hi Boo! Bad luck but far from the end of the world. I have had this happen many times with drills of many sizes! At least the hole with the broken drill in it isn’t going to visible so you have a few more options open to you. My preferred method would be to just carve away a bit of a countersink hole with a scalpel to expose the end of the drill and then use needle nose pliers to grab the end and extract it, pulling and twisting at the same time (make sure you get the direction of rotation right 🤣 🤣). I’ve always found that they come out far easier than I was expecting if you can get a reasonable grip on them. The hole can then be bored out to 4mm or 5mm and plugged with a hard wood dowel before trying the pilot hole again.

Darren

The magic starts at 3:10 - could have kicked myself...

https://guitarmaking.co.uk/lesson/drill-the-holes/

BTW: I'd use a 2.5mm for the bridge mount holes next time...

Measure twice, cut once...

BTW: I'd use a 2.5mm for the bridge mount holes next time...

@markbailey Thanks for that, I’ll buy some new drill bits. 2.5mm 👍

Make guitars, not war 🌍✌️🎸

Fixed the problem today. Made a cylindrical drill bit out of some brass tube and cut some teeth in the end of it will a Dremel. Drilled the snapped drill bit out using a drill guide for stability. I then plugged the hole. I’ll cut it flush tomorrow with my flexy Japanese pull saw.

Make guitars, not war 🌍✌️🎸

That came out great, nice and clean.

What kind of dowel did you use? I bought some plug cutters a few years back after getting tired of the softish hardware store dowel. I can cut plugs in whatever wood I choose and then you get face grain instead of end grain.

Nice save!

Practice on scrap...

Thanks @eddie6string and @mattbeels I used a bamboo plug. I bought a big tub of bamboo barbecue skewers a while ago from Aldi, I knew they would come in handy for many things. It’s a huge tub, they will last me years at this rate. Bamboo is strong so I know the screw going into it will get a solid grip. The repair is under the bridge and I’m giving this guitar body the full paint job so it won’t get noticed at all.

Make guitars, not war 🌍✌️🎸

Dude, check it out: I was just on the Siggi Braun website and they‘ve got a guitar for you!

@mattbeels I’m gonna sue. Using my brand. 🤣

Make guitars, not war 🌍✌️🎸

I'll share this week's disaster with you -

Final rubs of this P Bass with 1,500 - 5,000 grit prior to buffing.

Wipe off with damp cloth to remove residual dust/sludge and let it breathe off for coffee before Mop & soap...... I had a real "Nora Batty" (strong language for me!) Moment when it became apparent I had rubbed through and affected the Purple burst finish.

An entire day wasted trying in vain to match the water-based stain of surrounding area [virtually impossible with a burst finish], only to conclude complete sanding back to wood and start again!

Two + days I'll never get back!

Looking better now after 3 coats.

I wish they did UV in a rattle can!

As is now

As was yesterday

Moment when it became apparent I had rubbed through and affected the Purple burst finish.

@eddie6string Oh no! Sorry to hear this Eddie. I know how it feels, I remember in the first few years of being a paint sprayer, one of the common clock ups was rubbing through. I learned to despise it so much that I developed a better finish from the gun so I had very little flatting and polishing to do. For any paint sprayer, avoiding orange peel and dry spray are something you develop with experience. I had to hone my skill with the finish from the gun to reduce or avoid the rubbing and buffing. It is much easier to rub through with nitro so I choose 2k, which is also available in rattle cans.

It’s a horrible feeling though and I feel your pain, just take some comfort in the fact that we have all been there and there will be times in the future when we do it again.

It’s all part of the fun though and it gives you an opportunity to be a pro and repair the damage/accident.

Make guitars, not war 🌍✌️🎸

Feel your pain there too Eddie.

I think I've managed to burn through on every guitar I've sprayed clear coat on (the joys of only having a back garden for a workshop and using rattle cans).

The solution (for me) on the next build looks like being having nothing approaching a sharp corner anywhere on the body and total overkill on the amount of clear coat ...

Guitar making is the art and science of turning expensive wood into sawdust.

Thanks Rockpile 92

I'm the same scenario as you - miss my olde workshop!

Most of the time it works well, it's the cure time that drives me to distraction!!! The proverbial Guitar builders' string of indeterminate length!

Can't move on to acoustics until these are out the door. Anyone wsnt to write a song for our community called "Waiting for a Cure" ?

I'm thinking of trying epoxy coat on the next couple, but the edges seem impossible to avoid runs!?!?!?