I'm very proud of my F holes, they were a necessity to get rid of rusty nail holes.

No offence intended @robin!

The standard f-hole design is a, errrr, standard (!), so our eyes are used to seeing it on a guitar, and it looks “right” because it’s a standard.

I accept that my eyes / brain are unusual ....

😆

Online guitar making courses – guitarmaking.co.uk

I let the pattern bit ride with a little squirt of WD-40. Drill out as much holes close to the line, highly highly adviseable. Make sure your f hole template/pattern that you scroll sawed is not too thick and made of dense type of wood preferred. I find it to have less burn and easier on the router. The router does not have to work as hard. The thicker the template there would be more friction. A trim smaller router more suited for the job. Do not use a dremel! Find appropriate speed that works best for the wood you are going to route on. I go slightly slower high speed on softer woods. Practice atleast 10 or more times on scrap. When in doubt do not attempt. No shame in cutting by hand turns out just as good. Did I mention practice on scrap? It is a terrifying rush to do f holes on a router but I looooovvvveee f-holes! It makes a guitar a guitar! The hole in the wood. Love the feel the sound the vibrance that resonates on your belly when you play it. There is actually a scientific reason for that design, those that get it, get it. Those that do not, don’t get it all. I prefer a chambered/hollow guitar than a solid anyday. I think that is quite obvious. Although it is an added task that complicates your builds more, I prefer a chambered/hollow guitar than a solid anyday. Sonic qualities of controlling tonalities and feedback live was part of my playing back then.

If I can just add something to this conversation, I think @tv101 should surely agree with this for an alternative to F holes. 😁

False F holes, you don’t even have to route, just use decals. Surely this must be the end of the conversation now. 😁 🤣

Make guitars, not war 🌍✌️🎸

Surely this must be the end of the conversation now.

🤣

You are on the internet! No conversation involving opinions and taste ( or lack thereof ) ever ends!

@boo Haha! That Ibanez rocks! A good friend of mine had it once and sounded amazing. Gretsch had the fake holes first I believe.

I’m pretty sure that’s one of your own guitars, it’s probably best that I say nothing ....

@tv101 🤣🤣🤣🤣🤣

Make guitars, not war 🌍✌️🎸

Found this as I was tidying up (no, really, I was!) the workshop today.

One of my very early home builds from years ago. It was originally a complete guitar. But the (home built) neck was ambitious beyond my skills at the time, and the hardware was fairly cheap and nasty, so I trashed it some time ago.

I kept the body (cherry, chambered) because I liked the way that the colour of it was maturing through the years, and because I thought I'd "do something" with it one day.

Posting it to illustrate that holes can come in shapes and sizes other than f.

😊

Online guitar making courses – guitarmaking.co.uk

Posting it to illustrate that holes can come in shapes and sizes other than f.

@tv101 Yeah it looks quite funky that, maybe you should finish it, make a neck. It’s certainly a more contemporary idea than traditional F holes, I like it also. 😁👍

Make guitars, not war 🌍✌️🎸

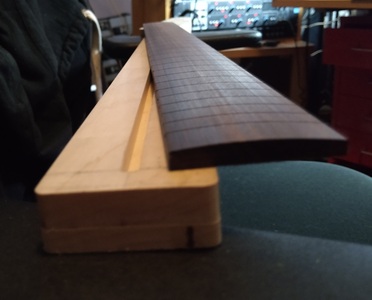

My first neck is going great! I guess that was the easy part right? 😀

So one weird thing: I used a 9.5 radius sanding block and ended up with a perfect 7.25 radius fretboard.

I really want a 9.5 So I guess I will need to flatten the middle a bit first and then go at it again with the 9.5 block.

Any better ways of doing this?

Another issue I had was that, although I measured twice, I still ended up with fretslots that where not perfectly square to the centre line somehow.

I have no clue why and how that happened, but I simply redrew the centre line so that my fretslots where perfectly square to it. Luckily I had enough material to work with.

For most of you guys this is probably easy, but for me it really feels like a victory and I am damn proud I am able to make this happen.

( And I am actually starting to enjoy working with wood and believe me, 'enjoy' and 'working' in one sentence is really hard for me to accept 🤣 )

Looks like you have the same type of metal fret cutting jig as me. The saw needs to be quite tight in the rollers or it can go off 90 deg. I’m assuming you have the fretboard stuck with double sided tape to the metal scale. I also use wooded wedges between the wood and jig sides to make sure nothing moves during cutting.

It looks like you’ve tapered the fb first before cutting the slots, or it was purchased like that. Makes it more difficult to get a 90 deg cut as there isn’t a 90 angle to measure from as a double check. To get exact centre I always make a small nick with a knife on the flat underside, just a snap off craft knife, as pencil points are not good for marking exact centre lines. You can put the ruler on the centre but a pencil adds a bit. Another way is to use vernier callipers to make a mark. The mark is hidden under the nut at one end and the other end is cut off.

Some people call me a tool, others are less complimentary. Tools being useful things.

The saw needs to be quite tight in the rollers or it can go off 90 deg. I’m assuming you have the fretboard stuck with double sided tape to the metal scale. I also use wooded wedges between the wood and jig sides to make sure nothing moves during cutting.

@rocknroller912. Yes, double sided tape and the saw is really tight against the rollers.

It looks like you’ve tapered the fb first before cutting the slots, or it was purchased like that. Makes it more difficult to get a 90 deg cut as there isn’t a 90 angle to measure from as a double check.

Yes the fretboard was slightly tapered to begin with. I thought it is wiser to assume that it is not 100% square anyway.

I never ever did any job that required me to make accurate measurements and cuts, so it is a learning curve 🙂

Accurate measurements are a learning curve. Mark was demonstrating recently how to fit position marker dots and showed how to double check before drilling with two different ways. This would be a good thing to work on.

Some people call me a tool, others are less complimentary. Tools being useful things.

Mark was demonstrating recently how to fit position marker dots and showed how to double check before drilling with two different ways. This would be a good thing to work on.

Thats one of the next jobs on the fretboard I guess.

Another issue I am also having is.. how do you make sure the nut slot is nice and square. I never get that 100% right. At this moment I use a small square file and a slightly too narrow nut with a piece of 100Grid sandpaper attached to flatten that pocket as good as I can, but still, I can wiggle the nut a bit vertically if I am pushing one end.

It s something I ve been struggling with on other guitars too.

I use the same set up as for cutting the fret slots but with a tapered fret board it’s more difficult to get it square. Clamps as well as tape can be used but the tightening will move everything off centre.

The fret template will have a mark for the nut take off point so I would mark this with the saw, then mark the thickness of the nut with a thin knife. This gives a mark for the second cut. Some nuts are curved on the bottom - get a flat one. It’s better to make the slot a bit tight and then scrape the nut to fit.

Some people call me a tool, others are less complimentary. Tools being useful things.

Some nuts are curved on the bottom - get a flat one. It’s better to make the slot a bit tight and then scrape the nut to fit.

@rocknroller912 That was what I meant. The slot needs to be flat too. It is not the position of the slot, but the bottom. I also only encounter it with Fender style nuts. On a Gibson style nut it is easier ( at least I think so )

@keondb

Ok I think I picked you up wrong. Do you check the nut to see if it’s flat, a lot of new ones are not. I use a thin chisel as a scraper to get the slot flat and check for rocking with a small engineers square. It just takes practice. You can rub soft pencil in the slot then the move the nut side to side. Where it rubs are the high spots.

Some people call me a tool, others are less complimentary. Tools being useful things.