Having laboured with the Selmer pliage soundboard guitar build for a couple of months now I have started what I hope will be a simpler distraction project whilst I get my head around exactly how to shape the sides of the petite bouche to accept the soundboard.

The new project is a couple of Concert model Maccaferri guitars which are the nylon strung classical guitars that share (almost but not quite) the same cut away body shape as the other Selmer Maccaferri guitars. With so much attention being paid to the connection with Django it is often forgotten that Mario Maccaferri was an extremely accomplished concert classical guitarist and was pretty good mates with Segovia!

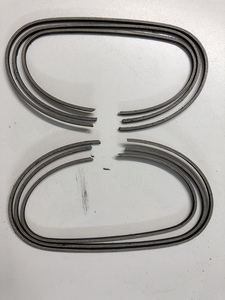

This model has a flat top (hurrah!), a normalish bridge and pretty standard classical fan bracing but it does have the large D shaped soundhole for which I am going to use three simple five band rings (BWBWB). The original guitar had the secondary Maccaferri resonator box installed but I am going to skip this until I have worked out exactly how to make it.

One guitar will be in Birdseye maple and the the other in tropical olive wood which looks a bit like zebrano but with lower contrast stripes. I have made the back of the latter as a four piece as the veneer I bought wasn’t wide enough to do it in two and it also gave me the opportunity to use the inlay strips between leaves.

Laminating the linings, veneering the headstock, sanding the front of the body prior to bonding the linings. Soundboards now pretty much ready to go bar for a little bit of final sanding. I like flat!

Not strictly accurate to the originals but I will sand the back of the body to a spherical R4800 as this is the only sanding dish that I have! I guess it won’t be far off and it should look fine.

Recent = Prevent!

I know that I have been posting progress on these under other topics but I thought it made sense to come back to the original one.

I made a vacuum bridge jig today which just seemed simpler than making up a set of mechanical clamps. I masked the soundboard around the outside of the bridge and also taped up the perimeter of the bridge itself to make clean up easier given that I couldn’t wipe the excess whilst still wet.

The jig was machined from 12mm solid laminate and I used 1mm latex both as the membrane material and to form the seal on the underside. The pump was an old oil lubricated unit which actually develops about 99.8% vacuum so the pressure was close to 1kg per cm2. No where near as much as can be applied with mechanical clamps but guaranteed to be completely uniform over the whole area of bond.

Once the jig was removed there was a bit of bubbled up squeeze out but not so much that I am worried about the integrity of the bond. When I glue the bridge on the second one I’ll but some duck tape on the underside on the soundboard where the two partial locating pin holes are situated to reduce the amount of air being sucked through the thin portion of soundboard at the bottom of the holes. You might be surprised at how much air you can suck through a piece of wood! Overall though it worked very well and was much less stressful than a whole bunch of heavy clamps.

Final coat of lacquer on the neck tomorrow and then it can be glued on and the last frets fitted. Not sure about banging these in so there could be another jig needed to enable me to squeeze them in in a more controlled fashion.

Vacuum clamp...... now that's something I hadn't thought of. Was the pump a medical one? I tried various pumps for a record-cleaner project. That must be a serious bit of kit.

Using cauls is one thing but the vacuum is a real game-changer.

Having seen the neat workshop that you inhabit, I think I need to clear my shed a bit.

The pump was an old Becker pump although I can't recall exactly when I obtained it. I think it runs at about 6m3 per hour, which is way more than is needed for laminating backs and sides in a (near) perfectly sealed bag, but the extra capacity is useful if you are losing any air through the substrate as it maintains a higher pressure differential ie clamping force.

I don't seem to have posted a pic of my Maccaferri Concert with strings on so here it is, hanging in a small Scottish cottage that may be known to some of you! I do need to unstring it again and have a go at the frets a bit, which is a drag considering how long it took to round over the ends and polish them! Still, if I play it really gently the strings hardly buzz at all! Maybe I just need a louder amp!

Looks lovely!

Measure once........ Measure again......... Sod it - make tea!

Pretty veneer though right?

That's a few steps beyond mere "pretty"! Looks like you've done it justice too.

There's a woodyard (old school) not too far from me that I visited a few weeks before lockdown. I was wandering around (old school) tripping over odd bits of timber, and the occasional 10ft stack of 20yo walnut planks, and then got into conversation with the guy who owned the place.

I explained the sort of thing I was looking for - ie anything suitable for guitar making, ideally with some interesting features/figuring.

"Oh" said Mr Woodyard Owner "you should have been here a couple of months ago" ... (you never want to hear that sort of comment) ... "I had a big stack of birdseye maple over there. No-one wanted it. Ended up giving it away".

I'll go back in a while, when, hopefully, he'll have decided that no-one wants his stack of walnut either ...

Online guitar making courses – guitarmaking.co.uk

I had a big stack of birdseye maple over there. No-one wanted it. Ended up giving it away

?

I have too many guitars...said no one in the world..ever!