I’ve just found something online that I find interesting. Some older guitars/stringed instruments don’t have truss rods installed in the necks. So, how could you adjust a bow in said necks if needed?

Well, something else I didn’t know is that, some stringed instruments have bar frets rather than T shaped (or tanged) frets.

Scenario: An old guitar had a forward bow in the neck when fully strung and tuned to pitch, and the neck had excessive forward bow, making it very difficult to play. The neck does not have a truss rod installed. What do you do to adjust the neck, bar removing the fretboard, routing a truss rod slot and installing a truss rod, before glueing the fretboard (or a new one) back on? Major surgery eh?

Well, if you remove some or all the frets and install some thin metal shims and reset the frets, it will straighten the neck up. Each little shim will add a little more material to the overall ensemble of the fretboard and in turn make the neck more resistant to any tension being applied to the neck with the string tension. Cool eh? 😎

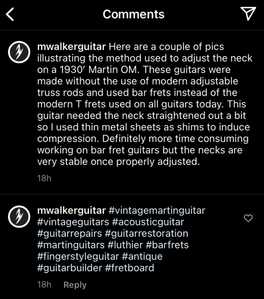

Here are some screen shots.

Make guitars, not war 🌍✌️🎸

Ive read about this method in a book by Irving Sloane on guitar repair. He calls it over size fret wedging and describes how it was used in the Martin acoustic factory in the days before Martin used truss rods on their instruments. Their method was to use frets with a wider tang.

Some people call me a tool, others are less complimentary. Tools being useful things.

@rocknroller912 It’s a great method. How would you go about doing the opposite thing, do you think? If the neck had a back bow? 🤔

Make guitars, not war 🌍✌️🎸

FYI: Fretwire is available with different tang widths - so it fits tighter or looser in the slot to allow for both forward and back bow situations like this.

We used to call it 'repair wire' and it was made by Jim Dunlop.

For a neck without trussrod with bowing issues you can also use a heat bending method:

Clamp the neck 'straight' whilst slowly heating and then cooling it over several hours.

All these techniques are potentially risky so not for the faint hearted or beginner unless you are willing to experiment and possibly trash the guitar... 😯

Measure twice, cut once...

FYI: Fretwire is available with different tang widths - so it fits tighter or looser in the slot to allow for both forward and back bow situations like this.

We used to call it 'repair wire' and it was made by Jim Dunlop.

For a neck without trussrod with bowing issues you can also use a heat bending method:

Clamp the neck 'straight' whilst slowly heating and then cooling it over several hours.

All these techniques are potentially risky so not for the faint hearted or beginner unless you are willing to experiment and possibly trash the guitar... 😯

@markbailey Oh very cool, I’m liking these advanced techniques.

Although I would be very wary of using the heat method on someone’s pride and joy, I would definitely do it on one of my guitars if the opportunity came up.

Make guitars, not war 🌍✌️🎸

You can try the back bow repair method first and let us all know how it goes.

ps have you got your spray painting demo ready for @tv101 when we do the video thing.

Some people call me a tool, others are less complimentary. Tools being useful things.

How would you go about doing the opposite thing, do you think? If the neck had a back bow?

How about removing the frets and then stinging the guitar for a while, under high tension if necessary. You could then refit frets with thinner tangs or carefully run your fret slotting saw in the existing slots to open them out again to standard width. I should point out that this is a purely theoretical solution, I have never done this myself. Sounds like a plan though!

Darren

How about removing the frets and then stinging the guitar for a while, under high tension if necessary. You could then refit frets with thinner tangs or carefully run your fret slotting saw in the existing slots to open them out again to standard width. I should point out that this is a purely theoretical solution, I have never done this myself. Sounds like a plan though!

@darrenking Thanks for the input. I can understand what you are suggesting but would the neck not just return to its original back bow when the over tension is returned to normal pitch tension? If so, the new frets would then become slack in the fret slots, even if they are glued in. I doubt a bit of ca glue would be strong enough to keep the neck in place and if it did, probably not for long.

I definitely can see the purpose of using strings as a tensioner/clamp though and maybe using the heat method that @markbailey mentioned at the same time, would work.

If I didn’t know any better, steam bending would definitely have a major effect but that is just being silly. 😆

Make guitars, not war 🌍✌️🎸

I had a good think about this and waited to see if there were any good ideas from others, so here’s my input.

A guitar with back bow on the neck and no truss rod is likely to have been made a long time ago so it may have been put together with water based hot hide glue, which isn’t that hard to take apart. I would take the fretboard off and see where the neck is. It might have been glued with a deliberate back bow which just was badly done and might spring back to a better position. There might also be room to plane the neck and glue the fretboard on flat.

Some people call me a tool, others are less complimentary. Tools being useful things.

Another thought. When I first started making in the 1980s I used to buy from a firm in Pennsylvania US who built a back bow in on purpose to counter string pressure. They had a jig for gluing up with a curve. It confused me for a long time until I started to understand more about guitars.

https://www.buckscountyfolkmusic.com

Some people call me a tool, others are less complimentary. Tools being useful things.

They had a jig for gluing up with a curve.

@rocknroller912 How interesting. Thanks for all of this info and input. 👍

Make guitars, not war 🌍✌️🎸

People have had some strange ideas on building in the past. Thank goodness for modern technology. I would be interested if you have one with a back bow.

Some people call me a tool, others are less complimentary. Tools being useful things.

I would be interested if you have one with a back bow.

@rocknroller912 I have an old acoustic knocking around somewhere with no truss rod, it does not play well. Lots of string buzz, it may have a back bow, I’ll have a look if I can find it. I’m willing to share it with you if you want to take it. It’s a bit beaten up so I could give it a new finish maybe. I’ll be north of the border soon anyway, so it will make life easier for some of us wanting to get together at some point. 👍

Make guitars, not war 🌍✌️🎸

I’m a sucker for lost causes, drop it in sometime if you are passing. I mostly do repairs rather than new building so I will be happy to give you my opinion. I’ve never found an instrument that wasn’t worth saving. I will leave finishing to you after any repairs as touching up finish is the hardest part.

Some people call me a tool, others are less complimentary. Tools being useful things.